ATTENTION!

Our website contains bows*.

If you are a visitor for professional purposes, log in as our pages contain information for professional purposes only.

In all other cases, please leave our site.

By clicking the "ENTER" button, you declare that you are a visitor for professional purposes only, and that you only need the information on the page for professional purposes.

*Based on the 175/2003. government decree, the bow is considered an instrument of increased danger to public safety. We are not responsible for violations committed with a bow.

ENTERTechnical informations

Basic information about bows

Warranty, pricing, pound-force, technologies, etc.

Technical Information

WARRANTY INFORMATION

There is no color shade guarantee for bows or accessories. So, if someone sees a light brown bow on the website, it is not certain that it will be exactly the same color in reality. Because no two natural skins are the same shade.

There can be a difference of up to 3-5 pounds between the ordered and manufactured bow, especially for strong bows and especially for bows made of natural materials.

We only guarantee bows used with strings made by us. If a bow is used with a string not made by us, the warranty will be void.

1. Bowing the bow

For reflex bows, bowing is one of the pivotal points. Quite a few people wind up their reflex bows incorrectly. Three things must be emphasized.

When lifting, the very center of the handle must be supported. Neither below nor above.

‘ After tuning, you must always set the string lugs in the middle.

‘ In the case of very sensitive bows, such as the TRH Laminated Turkish or the Composite Turkish, the degree of asymmetry in the bow may change in the case of bad bowing. It is important that this can and must be corrected. (see the photos in the Usage menu item or at point 13)

2. Definition of poundage, the strength of bows

All bows are measured at 28″, regardless of the maximum draw length of the bow. (the exceptions are the Child Scythian and Child Scythian bows).

Obviously, if one draws the bow further than 28″, the bow will be stronger. (The bow can only be stretched to its maximum draw length.) Typically, we can adjust the strength of each bow to anywhere from 25 to 120 pounds. However, there may be a few pounds difference compared to the order. By the way, most people these days choose a bow around 40 pounds. The old Hungarian, Turkish, etc. bows usually had a pull of 55-90 pounds. An average composite bow is usually ordered at 60 pounds, but 45 pounds and 90 pounds are also ordered.

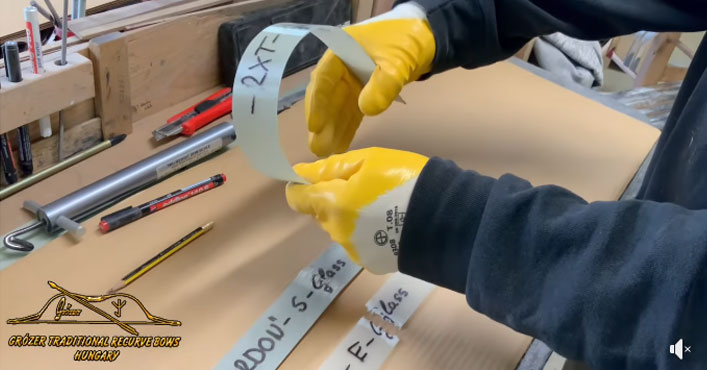

3. TRH technology

TRH technology refers to the special materials from which these bows are made. (consists of 6 different layers). Similar properties can be achieved with these materials as with Composite bows. Bows made with TRH technology are both soft when drawn and fast when shot. In addition, since they have little grip vibration, they are very accurate. Their stability is also greater than that of a bow made with simple lamination.

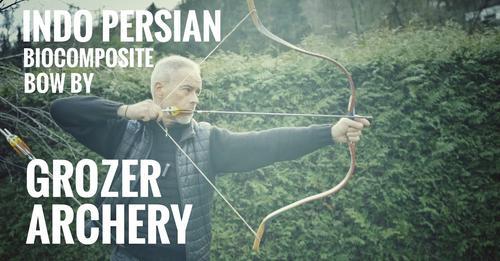

4. Biocomposite laminated bows

New technology.

It actually combines the laminated, TRH laminated, and TRH Extra II laminated bows.

In a way, the extra III bows too. Bows made with this method are made of the following materials: the middle layers are made of wood, the inner layer is made of pressed horn, and the outer layer is a pressed tendon plate. These two layers are glued to the wooden board with modern glue, and the glue layer is even reinforced with fibers.

Thanks to these biocomposite materials, as well as modern technology and materials, bows made in this way are faster than plain laminated bows. However, they are noticeably soft when stretched, have a long draw length and are resonance-free.

Shooting with bows made in this way is almost the same experience as with an antler bow, and their external appearance is also similar, only biocomposite bows are flatter.

5. The efficiency of the bow

The difference in the quality of two bows is caused by the difference in efficiency of the bows. So, if one bow is more efficient than the other, the more efficient bow will shoot the rod faster and farther with the same pull force than the less efficient one.

Bows can only be compared in terms of speed and range under the same conditions: the string length of the two bows must be almost the same. The pulling power of the two bows must be exactly the same. If, for example, we shoot with a 30″ rod when comparing the two bows, then the power of the bows must be measured at 30″ and they must be the same there.

If we compare the bows in terms of shooting distance, it is approx. Let’s do it in 40-43?, with rods of exactly the same weight and the same person shoots with both bows. (The maximum shooting distance ranges from 150 to 300 meters, depending on whether you shoot with, for example, a 45- or 80-pound bow. With 90-120-pound bows, you can shoot over 300 meters with a light rod.)

It is important to know that even a difference of a few meters means a big difference in efficiency between two bows.

The same is true for speed measurement. A difference of a few feet per second is a pretty big difference between bows.

6. Laminate bow or solid fiberglass bow?

Solid fiberglass bows are often referred to as resin bows, but this is a misnomer. Taking apart such a basic bow, it may appear that it consists only of a plastic sheet made of some kind of resin and reinforced with a few strands of glass fiber. In contrast, even the simplest children’s bows are made by impregnating various fibrous materials with a binder and compressing them into a shape. So, that’s why we call them solid fiberglass bows. In our technology, the resin is only present as an adhesive. (if, for example, wooden plates were glued together with resin, no one would call this bow a resin bow, but a wooden bow)

Many people think that laminate bows are better than solid fiberglass bows in every way, but this is not true.

We make a wide variety of bows, with various technologies and often combine these technologies with each other. To date, the most reliable bows can be made from standard designs. (It is no coincidence that the bent arms of compound bows exposed to high stress are also made with solid glass fiber technology). If we look at the price/usability ratio, then the basic type bows are certainly noteworthy, for example the Õsi Szkíta, Medieval Hungarian, Hungarian basic C, and the New Hungarian basic bow… etc. Of the laminated solutions, the TRH lamination has worked best, but the more recently produced plain laminated bows are also very good (e.g. Laminated Assyrian, which is one of our fastest bows, or the Laminated Hungarian B bow.)

7. Longbow or reflex bow

Today’s longbows and reflex bows can be grouped into 3:

A, Longbowk

1 / L ‘ Wooden Longbow (classic, straight)

2 / L ‘ Laminated Longbows (wood-glass lamination, straight)

3 / L ‘ Sport Longbows (wood-glass layering, reflex-deflex shape, window, pistol grip)

B, Reflex bows / Recurve

1 / R ‘ Horn-tendon reflex bows (composite bow)

2 / R ‘ Fiberglass reflex bows (wood-glass lamination)

3 / R ‘ Sport reflex bows (wood-glass layering, window, pistol grip)

If we compare a longbow with a classic shape and material and a reflex bow with a classic shape and material ( 1 / L ᐈ’ 1 / R), then in terms of its physical and other properties, the reflex bow will surpass the longbow to a large extent. There is hardly any difference in speed between a Turkish bow made of natural materials and a Turkish bow made of fiberglass materials, but between a longbow made of wood and a reflex-deflex longbow made with fiberglass lamination, there can be an incredible difference in quality in favor of the latter.

Nowadays, there are quite a few longbows that are closer to a reflex bow than a longbow in terms of shape (3 / L). In addition, today’s longbows are made with a composite solution, i.e. glass plate and wood are laminated to each other. In this case, there is no longer such a big difference between a reflex bow and a longbow, but reflex bows are definitely physically more efficient structures than longbows. It is very important, however, that a sport longbow (3 / L) cannot be mentioned in the same category as a fiberglass reflex bow (2 / R), but the sport longbow (3 / L) can only be compared with the sport reflex bow (3 / R). So it is also true that, for example, a basic Hungarian bow can be combined with a glass fiber reinforced longbow if it does not have a window. In addition, a basic Hungarian bow cannot be compared with a hunting reflex bow, since it has neither a window nor a pistol grip.

8. ‘About horse bows’

Many people think that Eastern reflex bows can only be used on horseback and mistakenly call them ‘horse bows’. You can shoot with any bow in the world from horseback, or from the roof of a house, or from the top of an omnibus. You can shoot with any traditional reflex bow in any conditions. So, if you want to shoot with a Hun bow, for example, you don’t need to put a horse between your legs.

Traditional reflex bows were not made for the horse, but were determined by the size of the materials used (horn – wood – sinew). That’s what made him the size he is. Some people think that if you use a reflex bow from horseback, you should choose a weaker one than if you were shooting on foot. I think this is also a big mistake. Everyone is given an optimal strength with which they can cope, and this is true regardless of the circumstances.

9. Stiff ends

Traditional reflex bows include longer ones, such as the Hun and Hungarian, and shorter ones, such as the Turkish. It is part of the truth that the two types of bow are one and the same in terms of their basic proportions. The difference between the forms resulted from the difference in the horn material used. For this reason, the structural design of the bows had to be changed. In Turkish and Scythian bows, the buffalo or Köszál goat horn reaches almost all the way through the bow, and here a part (2/3) of the rigid arm is formed from the bent arm.

In the case of Hun and Avar bows, the cow’s horn is only on the arm of the bow, so the grip and bow ends had to be stiffened with bone or horn plates. Since these bows were stiffened at the grip and ends, they had to be made larger to give the same draw length.

So, a Hungarian-type bow does not have a much longer z bow end than, say, a Turkish bow, because the power arm of the Turkish bow must also include what is bent in the negative direction from the bent arm.

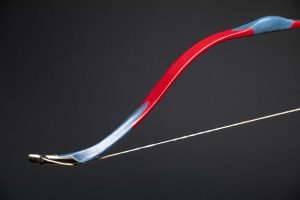

10. ‘C’ shape or forward arm?

In short, it can be said that the ‘C’ shape works better with relatively softer materials, such as horn and sinew; for stiffer materials such as glass fiber, carbon fiber, the bent arm form is best for a traditional bow.

The old horn bows also had bows with bent arms, especially those with a rather large grip angle, such as the Avar and Hun type bows.

11. Competition bow or hobby bow, i.e. speed or agelessness

With traditional bows, I think at least as much emphasis should be placed on age accuracy as on speed. Nowadays, some reflex bows or longbows are also made in a ‘sport version’, not only in the old form.

Ageism can also be divided into two parts. For example, a longbow or a Turkish bow can be completely corroded, i.e. corroded both in form and materials. At the same time, they can be partially old, i.e. they are formally authentic, but in terms of their materials, they already contain modern materials. It is important to note here that since more and more people are competing with traditional bows, the speed and accuracy of traditional bows are becoming more and more demanding. This expectation has a healthy effect on the production and development of traditional bows up to a certain level, but above a certain level it distorts traditional bows in a harmful and bad way. After all, if someone devotes himself to traditional archery, he must also respect the traditions on some level.

I think it is very important that some traditional bow types retain at least their formal characteristics. My personal opinion; that how similar a bow is to its thousand-year-old predecessor is at least as important as its speed.

12. Waiting period

In most cases, we cannot serve customers immediately from stock. There are two main reasons for this. One is that we make a great variety of bows in different colors and draw strengths, and this results in a huge possibility of variation. Thus, hundreds of bows would not be enough for everyone to find the right one for them. The other is that we are going in the direction of quality, although we are also gradually increasing the quantity. Improving quality involves continuous experimentation, which requires a lot of time.

Customers must respect that if they want to buy a quality product, most of which is made by hand, then the time factor must also be taken into account.

So you have to wait at least two months for the ordered bow, sometimes even more, and that’s not much at all.

Despite all of this, we still have bows in stock, and the majority of customers will find the right one among the bows currently in stock (especially if they are willing to make a little compromise, say, in terms of color).

13. Dimensioning of bows

If someone makes bows from original materials (horn – wood sinew), the size of the raw materials limits the possible dimensions of the bow. The proportions of the bow must be designed in such a way that it is on a human scale. So that the maximum draw length should be at least 28-30″.

The bows made by me with modern materials, but with a traditional character, were also made in such a way that we took into account the dimensions of the old natural material bows. I mean Scythian, Hun, Avar…etc. for bows.

Of course, since today’s average height is higher than a thousand years ago, we made the bows proportionally larger. Proportionality is the key word here, because if you increase the size of a bow, you usually have to increase the angle of the grip, for example.

Another important note about this is that bows only got bigger by the amount that people today are taller. However, since individual archery styles can vary, we have created longer-than-average draw lengths for most bow types. (e.g. there are basic Hungarian bows with draw lengths of up to 33-34″).

14. Composite bows

The term Composite or extra III means that the bow is made as it was thousands of years ago, i.e. from horn-wood-in. Because, the old eastern reflex bows, so the Hungarian, Hun, Avar, Turkish… etc. they were not only made of wood, but of materials much more flexible and tougher than wood: horn plate and tendon plate. Only the frame of the bow was wood. In the past, these types were simply called horn bows.

I have been dealing with this technology for the longest time, my first horn bow was made 19 years ago. Since then, I have been experimenting with these bows almost every day, I have worked with them a lot, and they have improved a lot. Composite bows produced in recent years are already competing with bows made of modern materials.

Composite bows are very sensitive to bowing (but not more sensitive than, for example, an Olympic competition bow). It is better to do squats with the help of another person. (see attached photo)

If, for some reason, the bow becomes very asymmetric, you must restore the appropriate amount of bending on the bowed bow by tilting it in the opposite direction and pulling it back as shown in the picture.

All in all, it can be said that this is still the best technology for the production of Hun, Hungarian, Turkish, etc. bows. Bows made in this way are fast, more stable laterally (twist less) and have less grip vibration than their modern material versions. In the case of composite bows, the full C-shape is achieved after placing the sinew layers on top. When the horn plate is glued to the wooden frame, the bows are not yet so C-shaped. The consequence of this is that after longer bowing, if the string is removed, the bow sags a little (actually, this is the original shape of the bow, as the horn plate was glued together with the wood), after about half an hour – 1 hour, the bow relaxes and the bow recovers C-shaped.

15. Properties of different types of bows

It is very difficult to distinguish between the bows I make, since they are traditional bows, and the most important thing here is age fidelity. That’s why it’s a difficult question when a customer asks what kind of bow I recommend. Nevertheless, I will still try to highlight some bows and describe their features, advantages and disadvantages.

Our most popular bows are still the basic Hungarian types. Since the end of 2004, we have been manufacturing them in a different way and from different materials, so these bows have a longer draw length, as well as become softer and a little faster. It can be pulled out to 31-33″ without hardening (they are made in several sizes, so it is worth specifying the desired length when ordering). From the spring of 2007, we put a new Hungarian base bow on the market. This new type already combines the good features of the old types A, B and C. The end of the bow is similar to the old type A, its drawn shape is between the old types B and C, and its maximum draw length and softness are better than the old basic bows.

Among the Hungarian bows, TRH Magyar is becoming more and more popular. It is a fast, stable and smooth bow. Another advantage compared to the basic types is that it has no grip vibration, which makes it more accurate.

The Medieval Hungarian bow is a very well-functioning and unique bow. In addition, it has a rather spectacular, decorative appearance. One of the fastest basic bows on the market. It is about as fast as a laminated bow, has little grip vibration and can be drawn softly and pleasantly up to 32-34″. This type, however, was not made on the basis of ancient finds. The Hungarian base C is a very fast, soft draw bow that is almost as stable as our old Hungarian base bow. (Hungarian base A). Its speed rivals that of laminated bows, even…

There is also a decorated version of the Hungarian basic type in types A, B, C. These mostly work like the longer draw length version of the basic version. In addition, there is also a more sophisticated basic Hungarian bow, which is based on the framework of the Mongolian bow. We also make Hungarian bows using the smooth laminated technique. The Laminated Hungarian bow is produced in a longer and shorter version. Light, accurate bows. The longer version has a very soft and long draw.

Without exception, Hun bows are very asymmetrical. Due to the asymmetric solution, the grip vibration is smaller than that of the Hungarian bow, and it is also faster.

Due to their shape, Assyrian bows are quite stable and quite fast when shooting. It’s a good experience to shoot with them. Among the Assyrian bows, the Laminated Assyrian bow stands out, which is one of our fastest and most accurate bows. It can be gently pulled up to 33″.

Avar bows have an interesting appearance and are quite old, but their draw length is short (max 28-29″). Some of their types have quite a large grip vibration if you use a light rod with them.

Among the Scythian bows, the Ancient Scythian is the most popular. Both children and adults can use it. Several people make a similar shape, but this is clearly a well-functioning bow from every point of view. It is not by chance that it is so popular. There is also a children’s version of this bow, which is only good for children.

The Adult Scythian bow is more of a mixture of an Avar and a Scythian bow. When bowed, it also resembles a smaller Hungarian bow. Models produced since 2005 have a longer draw length. There is also a children’s version of this.

Mongolian bows are thought by many to be the best, as they are string spacers, but they are by no means the fastest bows. Among the extra III bows, the Mongolian bow is the slowest, even slower than the Hungarian one. In the fiberglass standard version, the Mongolian is faster than the Hungarian. The pull length is approx. 32″.

A laminated version is made from it, called Traditional hunting reflex bow. This is a fast, light, accurate bow. Our hunting reflex bows with a new design are very attractive and extremely fast. Compared to this, the goods are extremely favorable. Longbows are made in various shapes and designs. Newer types of longbows are made of particularly beautiful woods. The price-quality ratio is also very good. Among the longbows, the Sport Longbow II stands out in terms of speed, which is a very, very fast bow.

All of the Turkish bows are made in a fairly C-shaped form (except for the Crimean-Tatar bow). Like Turkish bows in general, they are fairly small bows. Nevertheless, their draw length is long, at least 30-32″. And the TRH Turkish bow can be stretched up to 34″. The most efficient bow shapes for their size. Their grip vibration is small, so they are not only fast, but also accurate. One of the fastest bows on the market among traditional reflex bows made with lamination. Their shape is designed in such a way that, compared to their size, they do not close an angle that is too small when the string is stretched. Nevertheless, you have to get used to the small size. In the three-finger shot, the index finger is only slightly bent, but it is best shot with the thumb method.

16. Optimal draw length

For a person of average height (180cm), the possible optimal pull length is 28-30″.

17. Error percentage

Based on our statistics over several years, there are very few failures in our manufactured bows. In the last year, the quality has improved so much that the error in the bows is well under 1%, so it is hardly detectable in %. Despite this, it happens that there is a problem with the bow, but I think it is impossible to solve this perfectly. We constantly test the individual bow types, and if we can, we constantly correct any minor or major errors.

18. The maker’s personal opinion about each type of bow

We make a wide variety of bows. I like almost all types of bows. If I had to highlight something, I would put bows made of horn – wood – sinew in the first place. Not because they are the best performing bows, but because they are no worse than a fiberglass bow, but much more knowledge was needed to develop them and many more working hours are needed to make each bow. If anyone has ever attempted to make a reed bow, you will understand why I consider reed bows to be the pinnacle of bow making.

Everything you need to know about bows

Info Center

Read all about bows and accessories. Expand your knowledge on the subject so that you can indulge your passion for archery up-to-date and with due care!

Technical news, tests, descriptions

Information about bows

Frequently Asked Questions

Our Social Platforms

Featured Bows

Our bows, which are more special than average and define their product category, deserve special attention.